With around 800 employees, three production sites and almost 70 years’ worth of experience, Slumberland produces some of the finest beds available, including a range of cot mattresses for newborns to four year olds.

Manufactured at Slumberland’s dedicated nursery production facility in Taunton Somerset, the Slumbertime Luxury Pocket Sprung Mattress is a true ‘best of British.’ Featuring individual pocket springs and Oeko-Tex 100 certified materials throughout; the mattress includes a breathable and washable temperature control cover, anti-allergy Actipro natural treatment and a 2 year guarantee. In fact, everything needed to ensure your baby gets a fantastically peaceful and safe night’s sleep!

As a fan of this established brand and their award-winning Slumbertime Luxury Pocket Sprung Mattress we were excited to see how they are made, so let’s take a look…..

1. The first part of the production process is making the mattress borders! Slumberland use clever technology which combines layers of foam, polyester and glue to form a rigid border without the use of stitches. The technology uses a heat castellated roller to form the border.

2. The border is then attached to the bottom part of the zip. Slumberland use lock stitching on all their mattresses to ensure there are no loose threads on any of their mattresses. The last thing we want are our precious babies getting caught in any threads!

3. Next they attach their baby safe waterproof layer to the top of the mattresses. This makes the core of the mattress 100% waterproof and makes those little accidents easy to wipe clean!

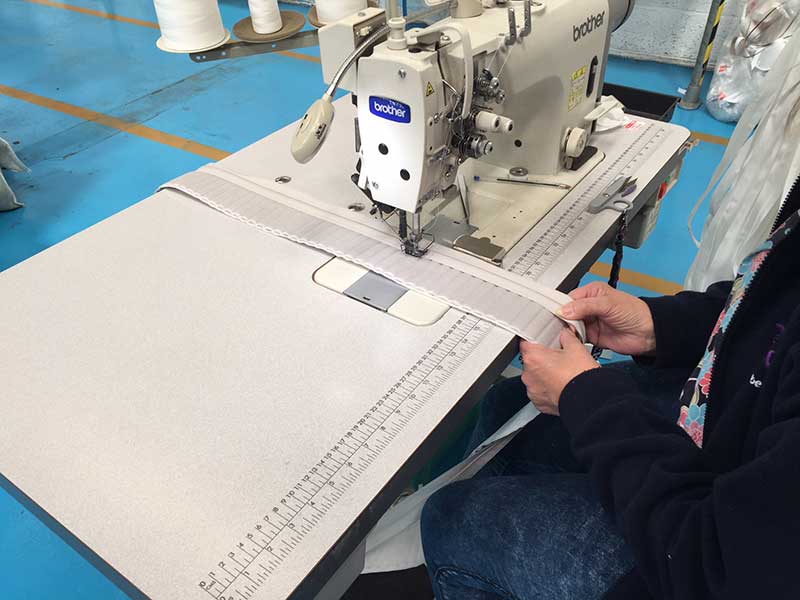

4. Now it’s time to attach the zip to the removable cover. This is a rather skilled technique and some of the dedicated workforce at Slumberland have been making cot mattresses for over 30 years! We are a big fan of Slumberland’s wonderful chemical free sleeping surface that is breathable, temperature controlled and benefits from a natural anti-allergy treatment to help prevent the harmful build-up of allergens.

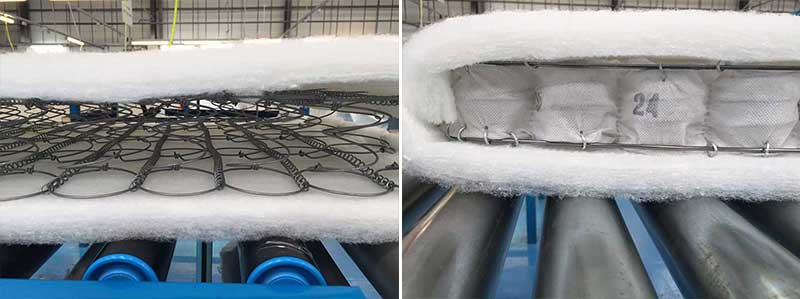

5. Once the cover has been made, it’s time to encase the springs with breathable baby-safe fibre. Slumberland use open coil springs on their Classic Sprung mattress (as shown in the photo on the left) to offer excellent comfort and support for babies throughout their development years. The Luxury Pocket Sprung mattress uses pocket springs (as shown in the photo on the right) which are responsive and encased in individual pockets to provide a more targeted comfort and support that contours to your baby’s body shape. The breathable baby-safe fibre and springs combine to offer an increased comfort and support which is just what we want for our sleeping babies!

6. The next process is to put the core of the mattress into the case. The Slumbertime Classic Sprung Mattress and Slumbertime Luxury Pocket Sprung Mattress are available in standard cot mattress (120 x 60cm) and cot bed mattress (140 x 70cm) sizes.

7. The next stage is to tape edge the bottom panel of the mattress to create a fully waterproof core! This is a highly skilled operation that takes an impressive 6 months of training to master.

8. The last stage of the production process is to zip on the chemical free sleeping surface to the mattress. And now you have a completed mattress! Which did I mention is award-winning! That’s right; the Slumberland Luxury Pocket Sprung mattress won ‘Best Safety Product’ by the Baby Products Association at the Harrogate Nursery Show in 2017.

9. Before packaging the mattresses go through strict Quality Control. We love that each Slumberland mattresses is inspected and signed off by the Quality Control team who also do a size check to make sure all mattresses are within tolerance - this ensures each and every mattress leaving the production facility is to the highest of standard.

10. Finally the Slumberland mattress is placed in a watertight bag and is ready to go!

We already loved the Slumberland Cot Mattress Collection, but after seeing the process from start of finish we could not recommend them more! With the whole process being completed here in the UK by Slumberland’s experienced and passionate workforce in their wonderful dedicated nursery facility, you really can be rest assured that all materials and workmanship are to the highest quality and safety standards – plus they have a 2 year Guarantee.

You can shop the range here.